Products

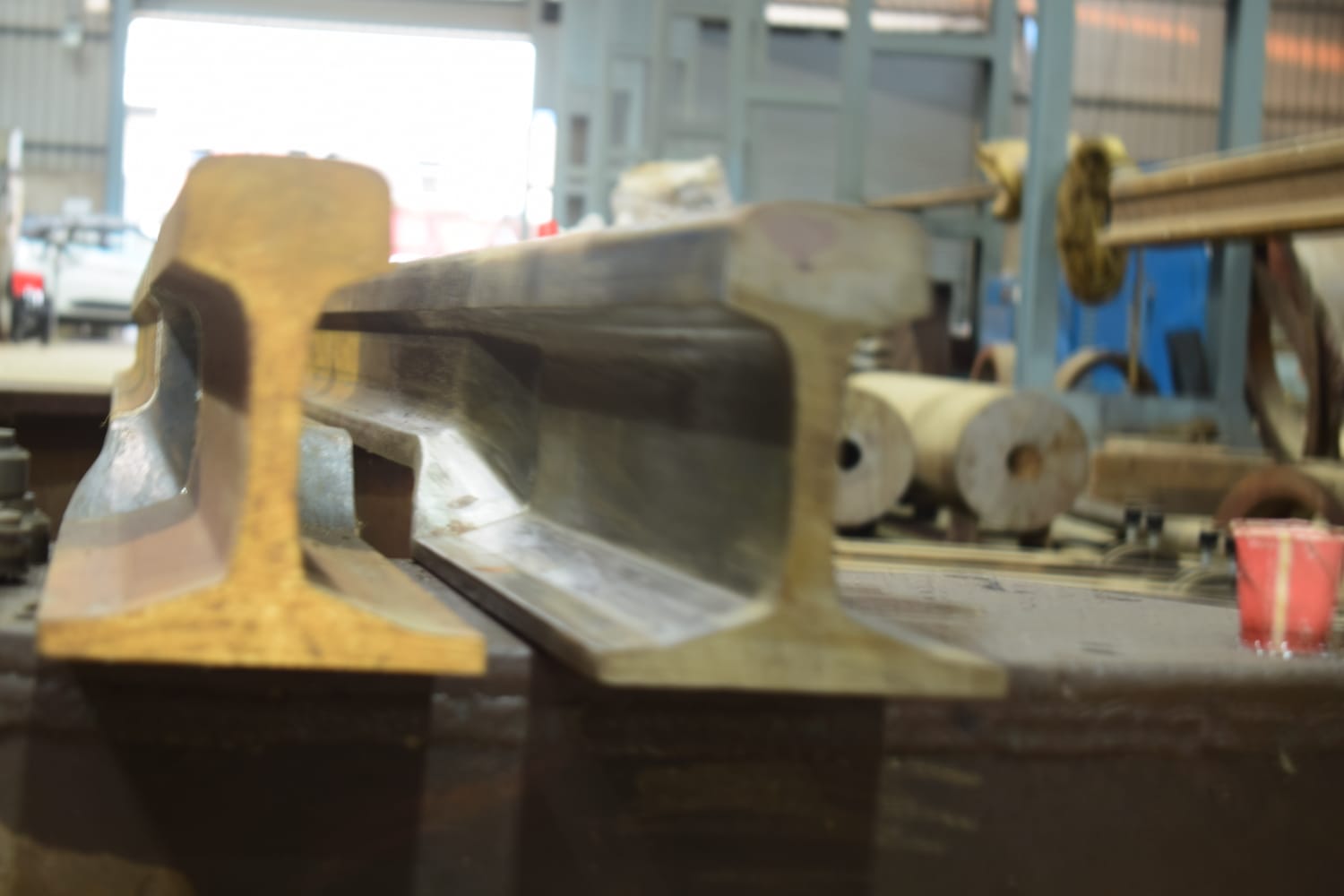

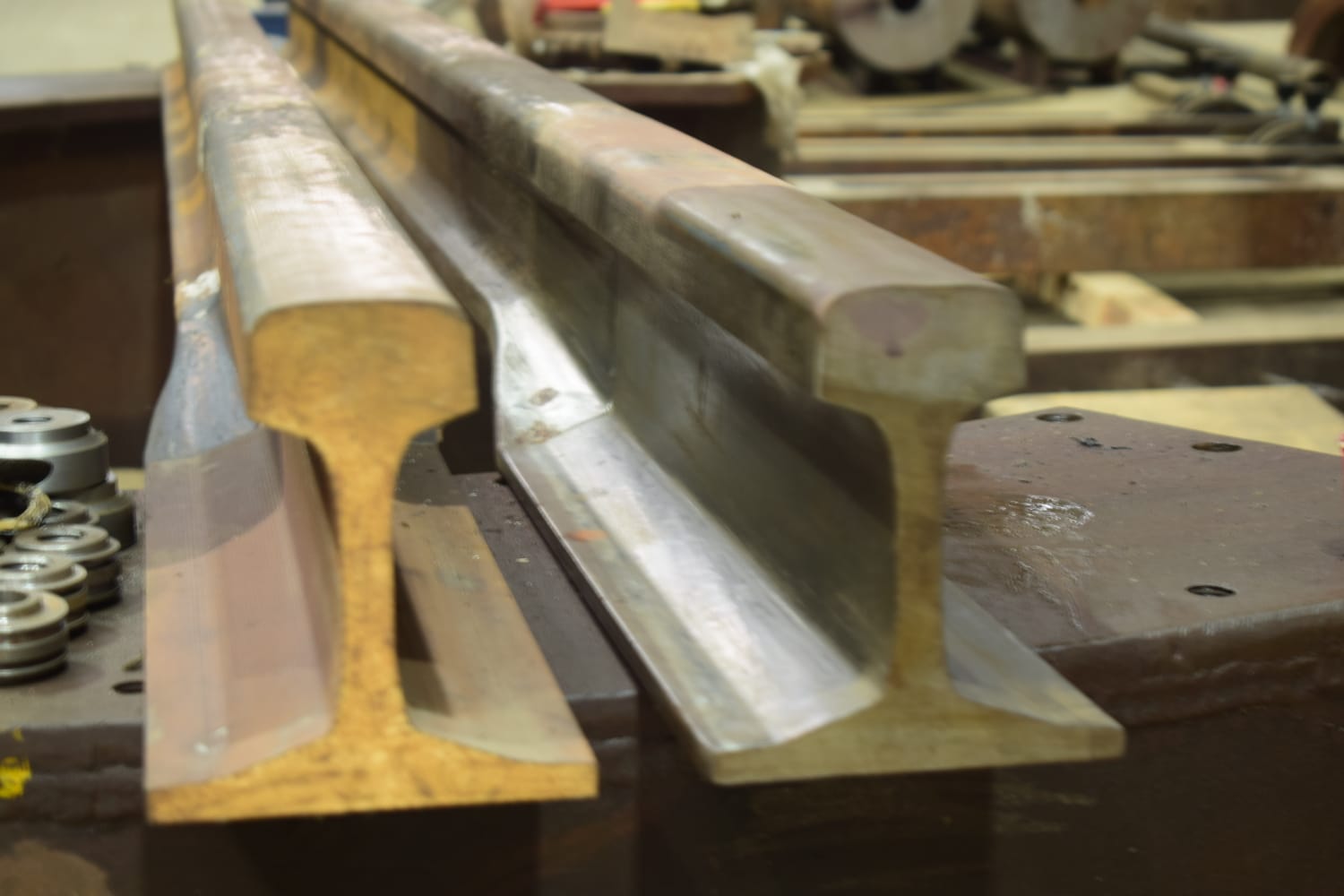

Asymmetric Rail End Forging

We proudly announce that we have successfully designed and developed an Asymmetric Rail End forging press which will cater to the requirements of Indian Railways. This is the first Press that is completely designed and manufactured in India with no Foreign Technical collaboration.The forging process is extremely unique and International Patent pending.

As demonstrated in the video available on this website, it is evident that the process developed by us is novel in nature. It employs the method of Progressive forging where the final die configuration takes the full shape of the section that is required. The press is Three-sided(lateral pressing from the sides and Top pressing) and consists of two forging stations. The Top cylinder has a capacity of 2500 MT's and the side cylinders have the capacity of 800MTs and 1200MTs respectively in first and second stations.By this process, we have overcome the challenges posed by the few existing machines and have eliminated the problems of forging laps, web over thinning, etc., this making our process more reliable, efficient and rejection free.

The company is poised to brand itself as

- a world-class manufacturer of the Asymmetric Rail End forging presses

- a capable conversion agent of these rails.

Currently, the company is in collaborative dialogues with various rail switch manufacturers, Steel plants and interested parties for carrying out forging and machining at our work on job work basis on a regular basis.Our current production capacity is 500 pieces of as-forged rails per month. Full fledged machine shop is expected to be commissioned in the subsequent quarter . Forging capacity will be enhanced to 1000 pieces per month by end of this year.